Unlocking Project Success: 7 Compelling Reasons to Opt for Customized Motor Controllers

In the world of automation, robotics, and precision machinery, motor controllers play a pivotal role in ensuring the success of projects. When it comes to applications like robotics, medical devices, factory automation, and more, off-the-shelf motor controllers might not always suffice. Customized motor controllers offer a tailored solution that can make all the difference in project success. In this blog, we'll delve into the reasons why opting for custom motor controllers, especially those employing field-oriented control (FOC), can be a game-changer.

-

Precision Matters: Tailored Solutions for Unique Applications

Customized motor controllers are designed with your specific project in mind. Unlike off-the-shelf controllers, which are built to cater to a wide range of applications, custom motor controllers can be fine-tuned to meet the precise requirements of your project. This level of precision is crucial, especially in applications where size and shape constraints are significant, such as medical devices and robotics.

Consider the case of a robotic arm used in precision manufacturing. The size and shape of the arm are often restricted to fit within a specific workspace. In such scenarios, a customized motor controller can be designed to perfectly fit the available space while delivering optimal performance, ensuring that the robot operates with utmost precision.

-

Enhanced Performance: Meeting the Toughest Challenges

One of the primary advantages of customized motor controllers is the ability to enhance performance. Field-oriented control (FOC), a sophisticated control strategy for electric motors, plays a crucial role in this regard. FOC allows for precise control of the motor's torque and speed, enabling smoother and more efficient operation.

In the field of robotics, precise control of motor movement is essential for tasks such as pick-and-place operations or delicate surgeries performed by medical robots. Customized motor controllers using FOC can significantly improve the performance of these robots by providing smoother motion, higher accuracy, and faster response times.

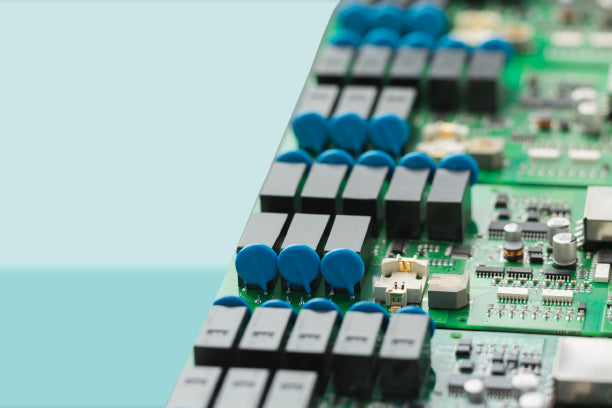

- Size Matters: Compact Designs for Space-Constrained Applications

In many applications, space constraints are a significant consideration. Custom motor controllers can be designed to fit into compact spaces, which is often not possible with off-the-shelf controllers. The ability to create a controller that matches the size requirements of your project can be a game-changer, especially in applications like medical devices where miniaturization is critical.

Consider the development of a portable medical imaging device. The motor controller used in such a device must be compact enough to fit within the device's housing while still delivering the necessary performance. Custom motor controllers can be designed to meet these size constraints without compromising functionality, ensuring that the medical device remains portable and efficient.

- Robust Reliability: Meeting the Rigorous Demands

Customized motor controllers are engineered to meet the specific demands of your project. This tailored approach allows for the inclusion of features and components that enhance the controller's reliability, making it better suited to handle the rigorous demands of your application.

In industries such as automotive manufacturing, where robots are used for welding and painting, the motor controllers must withstand harsh environmental conditions, including extreme temperatures, humidity, and exposure to chemicals. Customized controllers can be built with robust enclosures and protective measures to ensure they continue to operate reliably in such challenging environments.

- Versatility: Adaptability for Changing Needs

While off-the-shelf motor controllers are designed to be versatile and suitable for a wide range of applications, they may not always adapt well to changing project requirements. Customized motor controllers offer the advantage of adaptability, making them an ideal choice for projects that may evolve over time.

Consider a research laboratory using a customized motor controller in an CMM for precision measuring purposes. As research needs change and new equipment is introduced, the motor controller can be updated and modified to accommodate these changes seamlessly. This adaptability can extend the lifespan of the controller and reduce the need for costly replacements.

- Unleashing the Power of Field-Oriented Control (FOC)

Field-oriented control (FOC) is a sophisticated motor control strategy that custom motor controllers can leverage to optimize performance. FOC is particularly valuable in applications where precise control of motor speed and torque is critical.

In robotics, for instance, FOC can enable smoother and more accurate movement of robotic arms, making them suitable for delicate tasks such as surgical procedures. In medical devices, FOC can enhance the accuracy of diagnostic equipment, ensuring that patients receive accurate and reliable results. The versatility of FOC makes it a powerful tool that can be customized to meet the specific needs of your project.

- Ensuring Compliance in Medical Devices

In the field of medical devices, regulatory compliance is of paramount importance. Customized motor controllers offer the advantage of being designed with compliance in mind from the very beginning. This can save significant time and resources when it comes to obtaining approvals and certifications for your medical device.

Whether it's compliance with ISO standards, FDA regulations, or other industry-specific requirements, custom motor controllers can be engineered to meet these standards, ensuring that your medical device is not only efficient but also fully compliant with the necessary regulations.

-

Conclusion

In the world of automation, robotics, medical devices, and other precision applications, the choice of motor controller can make or break a project's success. Customized motor controllers, especially those employing field-oriented control (FOC), offer a level of precision, performance, and adaptability that off-the-shelf controllers simply cannot match.

When size and shape constraints are significant, when performance is critical, when reliability is a must, and when compliance is essential, custom motor controllers shine as the preferred choice. They are tailored to meet the unique demands of your project, ensuring that it not only meets but often exceeds expectations.

So, whether you're developing a robotic surgical system, a compact medical imaging device, or industrial automation, consider the advantages of custom motor controllers to unlock the full potential of your project and ensure its success. With custom motor controllers, you're not just controlling motors; you're controlling the future of innovation.

Leave a comment (all fields required)

Comments will be approved before showing up.